-

–RUGGED QUALITY ENGINEERING

-

–HIGH PERFORMANCE

-

–FAST INSTALLATION

-

–QUIET HYDRAULIC SYSTEM

-

–HIGH OPERATOR SAFETY PENDANT CONTROL

-

–FULL EXPOSURE OF NEW SERVICE WITHOUT REPOSITIONING THE WINCH

-

–EASY OPERATION

-

–EASY MAINTENANCE

-

–LOW COSTS IN LABOUR, PLANT & REINSTATEMENT

-

–ALLOWS FOR UPSIZING OF PIPES

-

–PROVIDES A LONG TERM SOLUTION

-

–ENVIRONMENTALLY FRIENDLY

-

–NO ROAD CLOSURES

-

–MINIMAL SURFACE DISTURBANCE

-

–LIMITED RE-INSTATEMENT WARRANTY

ADVANTAGES OF PIPE BURSTING

Most cost effective method

Of replacing water and

Sewer mains

Allows for upsizing

of pipes

Provides long

Term solutions

No road closures

Minimal surface

disturbance

Limited Reinstatement

Warranty

ADVANTAGES OF AUSSIEBURST

Rugged quality

Engineering

High Performance –

Fast Installation

Quiet Hydraulic System

Powerful Twin Cast Iron

Gear Pumps

Pendant Control –

Greater Operator safety

Double reversible

pulling Jaws

Taper threaded

pulling rods

Full exposure of new

Service without

Repositioning the winch

90 degree knuckle pullers

Easy to operate

And maintain

Designed for Contractors

THE PIPELINE PROBLEM

The failure of ageing sewer, gas and other utility pipelines is a global problem. Premature failure from tree root penetration, poorly aligned joints, ground movements, and services simply reaching beyond their expected life cause leakage out of and also into pipelines. Leakages are expensive leaving utility companies with a major financial headache. The options are, renovate the existing pipe or, replace – but which?

THE PIPELINE SOLUTION

There are many renovation systems on the market, mostly types of inserted liner or spray lining techniques. These systems can be effective, but generally only offer temporary solutions. Very often increased consumer demand requires upsizing the pipe to increase capacity. At best a liner will only restore the original capacity.

Putting off the inevitable is not usually cost effective.

The long-term solution is therefore replacement.

REPLACEMENT – HOW?

In the past replacement meant large open trenches, heavy machinery, road closure and consequently severe disruption.

Now Aussieburst the advanced trenchless pipe replacement system offers an efficient, environmentally friendly solution.

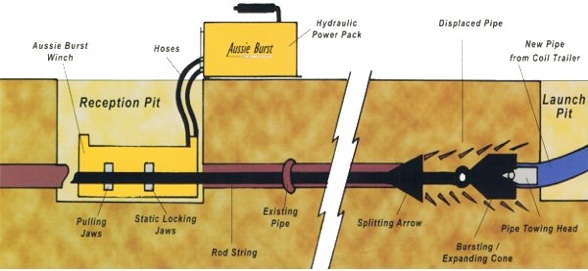

Aussieburst – a simple hydraulic push / pull rod system. First excavate 2 pits at a predetermined distance apart and break into the existing pipe. Install the hydraulic rod pusher / puller, then push up the old pipe the leading flexible rod called a teardrop. As the rod string advances the teardrop will faithfully follow the existing pipe. Upon reaching the other pit remove the teardrop and attach the appropriate splitting arrow, followed by the bursting cone and pipe puller. Attach the new pipe from the trailer mounted drum and reverse the hydraulic system to install the new service, upsizing if required. Move to the next in line pit to continue the process, butt welding the sections together for a continuous pipeline.

WHY HYDRAULIC?

The hydraulic system offers several advantages over pneumatic systems:-

*No contamination of the replacement pipe – air systems exhaust up the new pipe depositing oil deposits etc. which then requires treatments.

*Impact moles are very aggressive, heavy vibrations from this method can cause disruption to adjacent services and buildings. Hydraulic systems offer very little impact on their surroundings.

*Noise pollution from impact moles in sensitive areas can be an issue. The hydraulic system just has a sound proofed power pack with very little intrusion.

THE COMPLETE SYSTEM

This simple, rugged and reliable system, quality engineered to withstand harsh Australian conditions, has an extensive range of tools and accessories as standard.

Pendant control – allows the operator to work outside the pit in absolute safety.

Taper threaded pulling rods – coarse taper threads allow for quick and easy connection / disconnection of the rod string. Hand tight is quite sufficient. 2 steel stillages are provided for storage.

90 Degree knuckle pullers – allow pipe installation in tight situations.

Featuring a sound proofed power pack, housing a reliable liquid cooled Kubota diesel engine driving twin cast iron hydraulic gear pumps, producing maximum pulling force of 40 tonnes at 4000psi.

Double reversible pulling jaws – the twin jaw system allows a full 600mm pull with no spring back on the new pipe. The fixed jaws hold the pipe string tight ready for the next pull. The jaws ‘float’ to allow for misalignment between the rod string and the pipe.

Full exposure of the new service – the replacement pipe can be pulled all the way into the reception pit without repositioning the winch. This leaves the new service ready for connection as soon as the winch is removed.

THE HIGH PERFORMANCE SYSTEM

Aussieburst – a fast and efficient hydraulic pipe replacement system.

Capable of replacing most pipes from 50mm – 350mm, the Aussieburst breaks out the failed pipes and replaces with new in 1 smooth operation. Aussieburst develops up to 40 tonnes pulling power and is capable of bursting cast iron, ductile iron, concrete, asbestos cement, pvc, pitch fibre and clay ware. Aussieburst is now being used to replace many types of pipelines including water, sewer, gas and communication ducts.

Aussieburst offers contractors a cost-effective alternative to traditional open trench replacement methods, whilst fulfilling ever more crucial environmental issues. Relatively small access pits mean less intrusion on the local environment, no road closures offers clear advantages on today’s increasingly congested roads and minimal reinstatements means less road damage with associated repair problems and warranties.

A PROFITABLE SOLUTION

Capable of installing 100m of new service in just 35 minutes, making it possible to install 200m+ per day, the Aussieburst offers significant savings for contractors. A reduction in the use of heavy equipment and traffic management, a reduction in reinstatements offer immediate direct saving, not to mention the reduced impact for the general public.

Simple to operate and maintain, Aussieburst is designed for contractors and rental companies. Full training is given as part of our service.